Musi Banyuasin is one of the regencies in South Sumatra province, Indonesia, with Sekayu Town as its capital, and Sultan Mahmud Badaruddin II International Airport in Palembang is the nearest airport. From Palembang, we can easily get to Musi Banyuasin by a car that will take about three hours with good road access. If we don’t want to drive on our own, there are several car shuttle services and also public transportations that travel from Palembang to Sekayu on a regular basis.

Tips: Search on your favourite search engine using the keyword “transportasi palembang sekayu” and you will see the information on the transportation company that provides shuttle van or bus services from Palembang to Sekayu and returns on your search result page.

TABLE OF CONTENTS

Musi Banyuasin and Gambo

When I shared about the making process of Batik Gambo on my Instagram story one night, a friend replied to the story. She informed me that from what she was told, only fabrics that involve wax-resist dyeing in the making are called Batik. The overall look is similar to Batik. It is no wonder that people define it as Batik, including the locals in Musi Banyuasin. While she may be correct to a certain extent about the absence of wax usage in the making process can’t be considered batik, we could probably say Gambo is a type of Batik that is done using a different kind of technique.

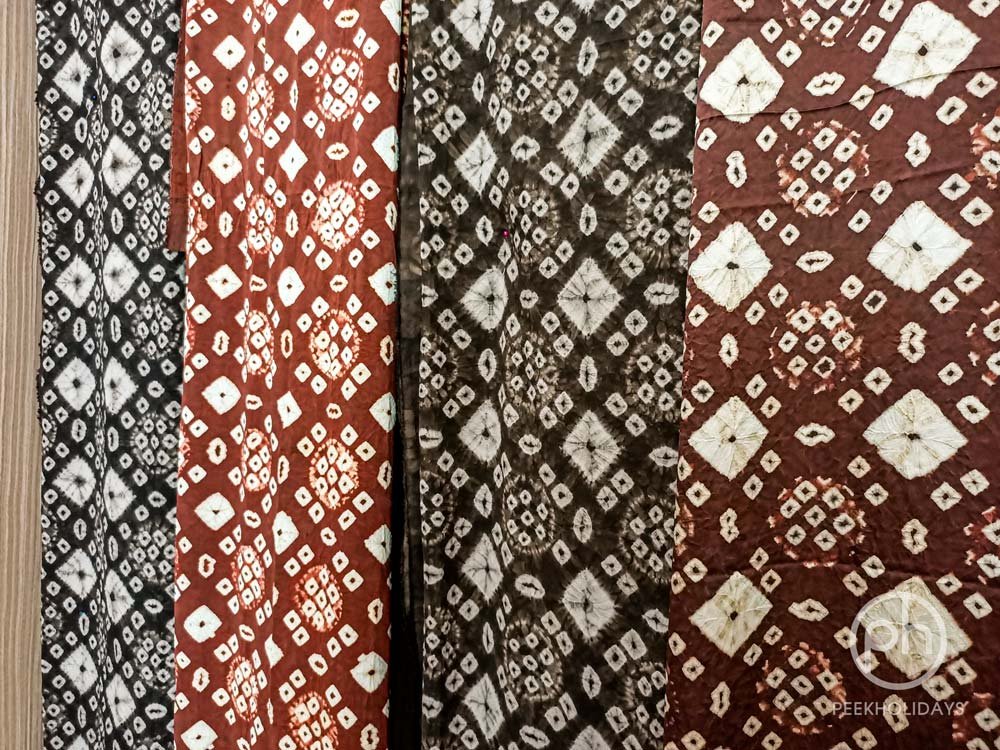

Gambier Plant is an essential component in making Gambo. That is how the name of Gambo come about. The extract of the plant is commonly used in cosmetic and pharmaceutical industries, while the mucilage that used to be discarded is now playing a big part in the dyeing process to produce earth-tone color. Unlike the making process of Batik we see elsewhere that use waxing, dyeing, and de-waxing method, the technique used in making Gambo is called “Jumputan” which involves pinching and tying the fabric bit by bit with raffia based on the pattern drawing. The area covered by raffia will remain as white or as the original fabric color during the dyeing process.

Gambo Making Process

From what I saw at the Ulak Teberau Village, one of the villages in Musi Banyuasin where we can see the Gambo making process, the first step the Gambo maker did is to trace the pattern on the fabric. So, they already have the fixed drawing that the local artist has designed. Then, they lay the plain fabric over the picture and trace it according to the graphic underneath. Although we may think it shouldn’t be that difficult to do, tracing on such a big piece of fabric does need skill and patience.

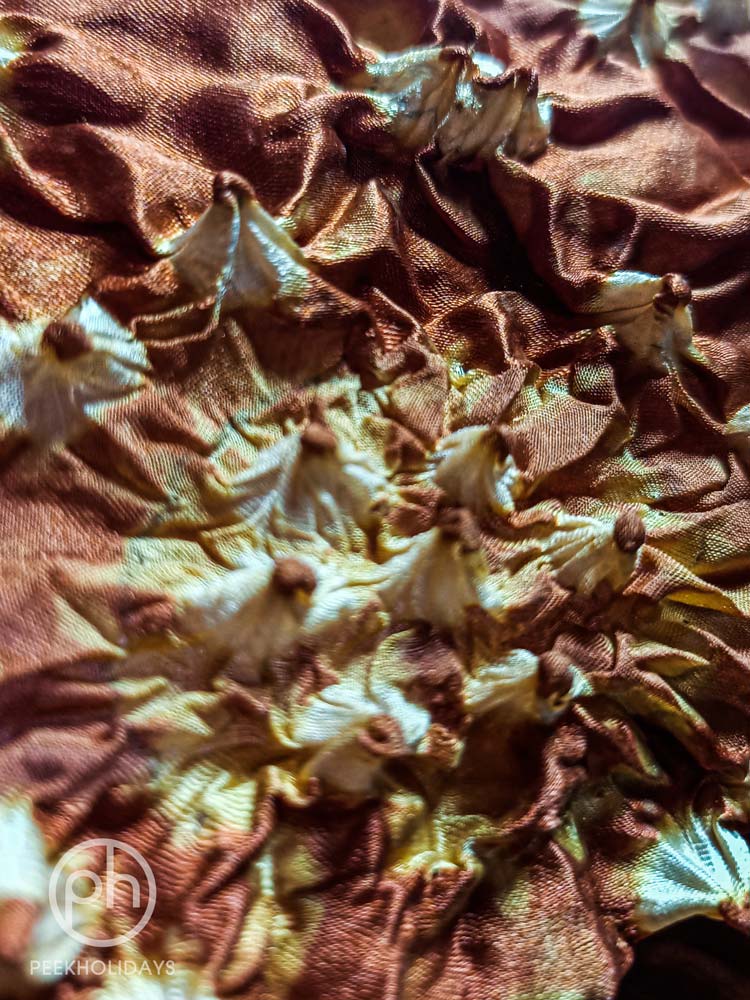

Though it is not limited to these choices, they usually use cotton and silk. After the tracing stage, they will start tying the part meant to stay without color with very fine raffia. I think the tying step needs another whole new level of patience, and I don’t think I have such long patience—one pinch by pinch, from one end to the other end of the cloth. When I saw how smooth and fast they do that, I could only stand aside watching and taking photos of them.

After tying is done, the fabric will be dipped into the extract of Gambier Plant, which in the past it was taken as liquid waste. The material will turn a little yellowish, and it is only the beginning. The part covered by raffia will not get contaminated by any liquid. Hence, it will stay white or as per the original fabric color. To produce the color, the fabric has to be dipped again in either limewater (air Kapur), alum (Batu Tawas), or Tunjung liquid that each reacts as a catalyst to Gambier.

Fabrics dipped in limewater will produce brown color, while black for Tunjung and red for alum. Because all colors come from natural ingredients, the colors produced tend to be darker, not as colorful, and bright as synthetic coloring. After the dyeing process is completed, they will hang it up for air dry without direct sunlight. The method may take days for a complete dry. After drying, they will still need to untie one by one and iron the cloth neat if they prefer. After that, it is ready to use.

Gambo and API Awards 2021

Gambo cloth has won 1st place at API Awards 2021 in the Souvenir category, topping the other nine nominees that had made it through the top 10. This time, Musi Banyuasin as the host of the API Award night shall be proud of their unique local creativity even more. The number of people aware of Gambo will increase, and it will affect the popularity of Musi Banyuasin itself for sure.

In my personal opinion, Gambo cloth is unique not only in the making process but also in its overall look. The feel is different, especially when turned into ready-wear clothing. Friends and I had the privilege to wear one during the API Awards night as outerwear. It was light, so it is still comfortable to wear under warm weather like Indonesia. It looks classy and elegant, and even so, it still looks good on guys.

It is recommended to get one as a souvenir when visiting Musi Banyuasin. And indeed to visit the village to see the making process with your own eyes, will be worthwhile, too! So, one more into your travel bucketlist!